How to perform a compression test on a Ford Focus ST

Posted on June 7, 2014

Compression tests are a very important tool in assessing your motor’s overall health. An especially convenient time to do this is when you are checking your car’s spark plugs. It’s also good to get a baseline compression test before adding parts or tuning the ST. A weak compression test result is something to be investigated further as it can be an indication of a mechanical failure (worn rings, poorly sealing valves, etc.)

On the Focus ST checking your compression is quite straightforward:

Step One – Prepare for testing:

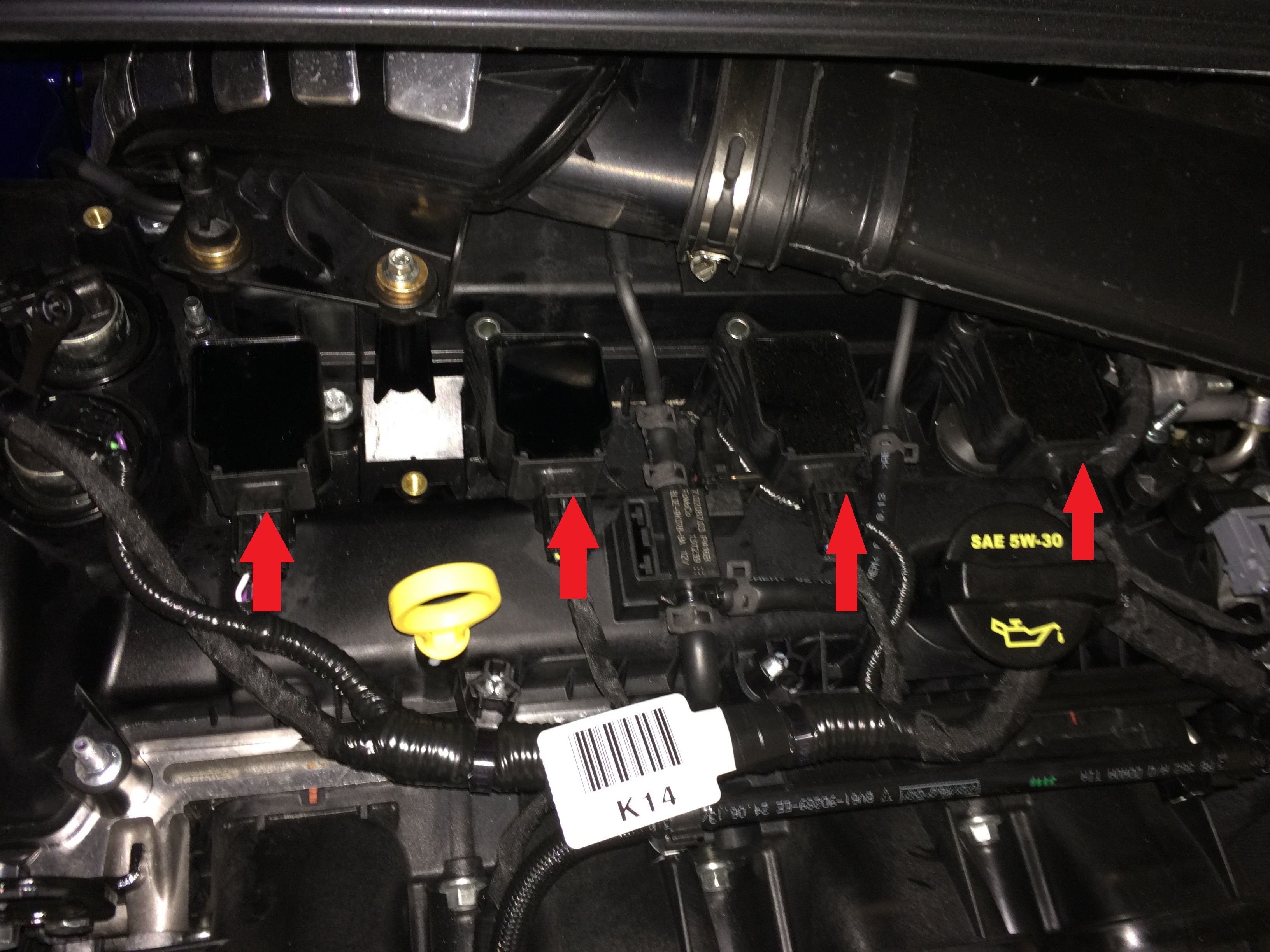

Preparing your Ford Focus ST for compression testing could not be any easier. First drive the car so that it is decently warm. Park it and carefully pull off the coil packs and remove all four spark plugs.

Step Two – Install the Compression Tester:

You can purchase a number of compression testers and they range in price and quality. Some of the very low quality ones can give poor or erratic readings. So if you get abnormal readings on an engine running well, then it is worth trying another tester. The compression tester simply screws into your spark plug hole. Make sure the O-ring makes contact with the cylinder head in order to prevent a false low compression reading.

Step Three – Test Your Compression:

To do this you simply push both the accelerator and the clutch all the way down. Once the clutch and accelerator are depressed press the start/stop button to begin the cranking process. Wait until you’ve heard about 15 cranks of the motor then press the start/stop button again to stop the process. Keeping the accelerator down the entire time prevents the injectors from firing while testing compression. If you have a friend helping; have them watch the gauge – ideally you want to crank until the needle stops moving up.

Make sure that you allow the same cranking duration for all four cylinders to allow for consistent readings.

Interpreting the Results:

Compression numbers will vary slightly from motor to motor but for a healthy internally stock ST motor expect around 160-170 psi (~11 bar) at sea level on a mild day.

The altitude and internal engine changes (pistons, cams, etc.) will affect compression readings. With altitude, the higher you go in altitude the lower the compression will read and this is perfectly normal. Multiply sea level numbers by the table below corresponding to your altitude to get what you should expect if you are testing at higher altitudes. For example a healthy ST motor with 160psi compression at sea level will have a compression of (160*0.8617) around 138psi.

1000′ = .9711

2000′ = .9428

3000′ = .9151

4000′ = .8881

5000′ = .8617

6000′ = .8359

7000′ = .8106

8000′ = .7860

Another indicator of a healthy motor is that the compression is fairly even across all cylinders. The rule of thumb is that all cylinders should be within +/-10% of each other.

If you suspect there is a problem and repeated compression tests indicate this, you will likely have other running issues such as oil consumption, fouled plugs, misfiring, etc. The compression test can identify the problem cylinder and you can then investigate further. The next step would be a leakdown test to show you where the compression is escaping (past the rings or past the valves). This requires more equipment so the beauty of the compression test is that it is quick and inexpensive with minimal tools needed.

Record the readings in order and keep the records to track the health of the motor and catch any issues if they show up later down the road.

Happy Testing,

The Stratified Team