I've been kicking around exhaust ideas for a while. After reading some of my questions, Spartn27 contacted me and explained he is starting up an aftermarket components company to build and market some of his ideas that he would like to see in the aftermarket world. He pitched me an idea for a prototype he had in mind...using similar technology to the Nissan GT-R exhaust. So before I go any further I have to extend a HUGE thank you to Spartn27 for reaching out to me with his ideas, and including me on his build.

We hashed out the details for a couple weeks and the research was ridiculous. After everything checked out, and the parts arrived, it was time to find a shop that would / could give us what we wanted. I landed on G&M Express in Holland, MI. Kind of a hole in the wall shop to be perfectly honest; but they had all the answers I was looking for. 30+ years of combined pipe bending between the two installers (one of which was the owner, Glenn). They subscribed to the mantra: "bending pipe is art...and you can either draw good, or you can't"...also Glenn calls everyone "Papa". LOL

I made an appt. for this afternoon, and we got right to work. They were cool with me being very active in the bay with them to get everything just how I wanted it.

**DISCLAIMER**

Beyond discussing the details of this build with Spartn27, I have NO affiliation with MDesigns or G&M Express.

First step was cutting out the stock exhaust, right up to the downpipe flange. So, let's talk about what it is we're replacing:

On the left end you can see the flex pipe on the downpipes going into the flange. From there, dual 2.25" pipes enter and exit the third cat, and go straight into the resonator.

This is what the 3rd cat (left) and res (right) look like off the car:

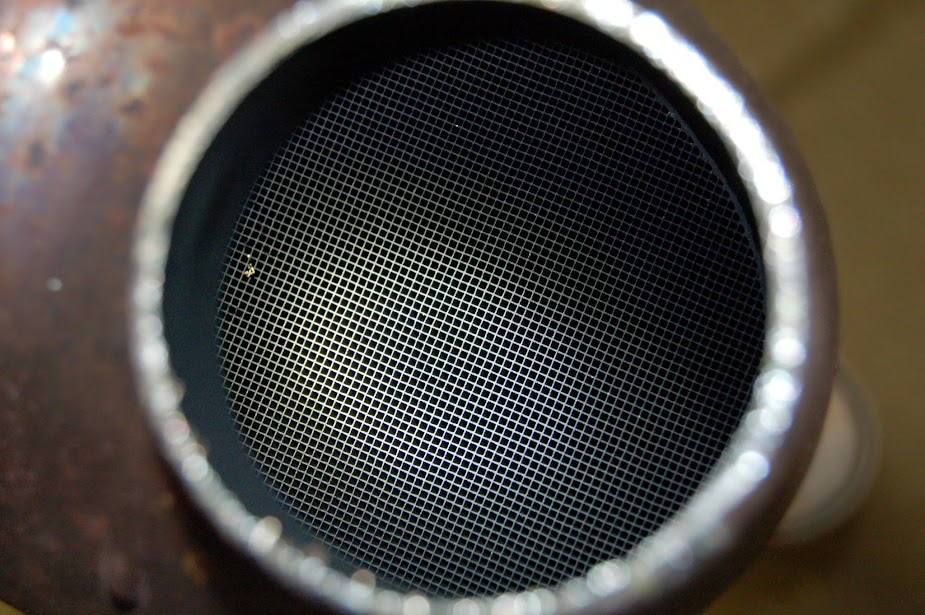

Looking down into the inlet of the third cat. You can see the steel honeycomb (looks like a fine mesh) that runs the length of the cat (about 10").

Looking down through the outlet of the resonator...Much to my surprise, this looks like it's just a straight piece of solid 2.25" pipe (x2) that runs the length of the resonator. My guess is it decreases resonation through the sound-deadening properties of sheer mass alone (res body about 20" long).

The dual 2.25" pipes leave the resonator and travel back to double 90* bends

Then snake up to stock mufflers and 4" Chrome tips

Looking backwards through the OEM muffler outlet you can see it's straight pipe back to the front of the muffler, where there's a flat wall, and an opening. This tells us the OEM mufflers area chambered muffler...which I'm pretty sure is BAD for turbo's since it can create a shockwave that travels back to the turbo. Maybe less of an impact being that it's at the end of the road.

Now...on to what we put in it's place. Let's start with the front.

I had him leave the stock downpipe flanges in place for easy connections once I spring for EPP DPs.

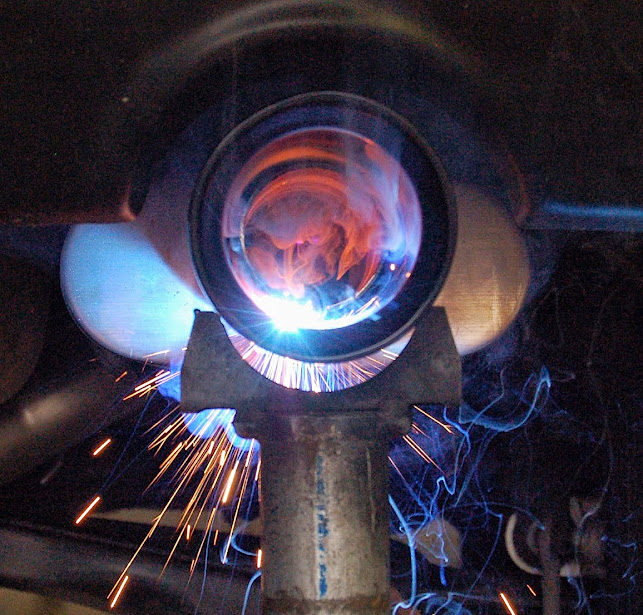

First step was opening up about a 3" long piece of stock 2.25" pipe on the rear side of the OEM flange, to 2.5" ...x2. Then welded on 2x 2.5"-bends to widen the birth from the stock flanges, outwards.

The wider birth was needed to make the connections from the flange to the new resonator. The body is a 4"x9" oval, and is only 11" long.

Magnaflow Dual 2.5" straight through, in/out. NO-X.

Two more 2.5" bends coming out of the resonator, to reduce the birth narrower for the Y-Pipe...Yeah you heard me...Y-Pipe!

Magnaflow dual 2.5" into single 3" Y-Pipe. The purpose of reducing down to a single larger diameter pipe is to reduce surface area. Two 2.5" pipes have far greater surface area than a single 3". When you're talking laminar flow, surface area is bad. Not only does it create skim loss wherever the gasses drag across the surface, but also acts as a heat sink to cool the gasses, which makes them more dense, and again slows them down. By using a single large diameter pipe we're able to keep velocity up, friction down, and maximize the inside area of the pipe for better flow.

Not to mention all of the benefits of an X-Pipe; harmonizing exhaust gasses, etc.

Simple math would appear to give you more inside area with 2x 2.5" pipes than a single 3"...which is true...but with the added friction loss from smaller pipes, inside area is no longer the winning attribute in hyperphysics.

The single 3" pipe then travels back to where the original 2.25 pipes hit their 90's and enter another Y. This time it's backwards - Single 3" to dual 2.5"

Setup so far

From here, each 2.5" outlet is met with a single 2.5" dual 90* pipe, on an upward angle to each muffler.

...as such

Magnaflow mufflers are a similar straight through design to the resonator. Only difference being they have a slight bend in the center from offset in, center out. Same dimensions as the resonator; 4x9" Oval 11" long.

A small piece of 2.5" was welded in, to bridge to the tip

And the tips were welded in place.

2.5 to 4" Double wall stainless tips. These were originally chrome, but were professionally stripped and powder coated satin-black.

Ditto for the other side

It doesn't look like it because of the bend and the angle taking the pic from, but the center section of 3" is about 4.5' long.

Finishing touches and adding the final hangers to line up with OEM

Shot from front to back

After everything was welded in place, the entire system was coated in matte-black ceramic exhaust paint (mufflers, tips, and resonator excluded).

The result was unlike anything else currently offered for our platform. Rather than trying to make it sound like a big V8 (which is isn't), it makes it sound like what it is; a twin turbo charged, high performance, work of art.

There is ZERO buzz or rasp.

The exhaust note is VERY deep. It sounds like a 12" subwoofer just humming away.

From inside the cabin you can hear a quiet low tone that almost disappears with throttle. Cruising speed, the sound is noticeable, but not obnoxious and has no drone.

To be honest I was actually a little disappointed initially because it sounded so quiet, but after getting out and walking around the truck I noticed is has a different personality from outside the vehicle.

There really isn't any 'bubble' or 'camming' sound, it's very smooth and consistent (courtesy of our giant x-pipe (aka the 3")), the note is so smooth and deep you can feel it in your chest.

Volume is on the lower side, and overall pretty quiet with throttle.

When you let off the throttle from a rev it has a slight 'falling over itself' tone.

I'm terribly curious to hear the change once I start messing with downpipes and or intake.

No turbo whistle is audible, just like before....yet.

Butt-dyno on the way home felt like it pulled harder, but that's so subjective you'll have to take it for what it's worth.

Due to the exotic sound of this setup, I'm having a hard time providing anything remotely close to accurate with a sound-clip or video. It's just so low I cant find a mic to pic it up, but I'll play with that tomorrow too.

More follow-up and adjustments to come...but I teased you all enough throughout the day, I knew I had to get something posted! ;D

I got a decent video today, and some enlightening tinkering results!

[size=18pt]

First Video: Stock Exhaust.

Stock air box + K&N Panel Filter. No engine mods. No tune.

http://youtu.be/XhgJGxbDtsA

Second Video: A look under the XSport at the finished / installed MDesigns system from flange to second Y.

http://youtu.be/GBHfPDFuZR8

Third Video: MDesigns Exhaust Prototype

Stock air box + K&N Panel Filter. No engine mods. No tune.

http://youtu.be/y9wq6Zn83xM

As for the results of the tinkering:

I was curious where the restriction was, now that the exhaust was free'd up and I still couldn't hear any turbo noise over stock.

With an open airbox and no filter...no turbo sound.

Open downpipe flange...still no audible turbo noise.

Then both open downpipes and open intake. Still no change in turbo noise.

This leads me to believe the main restriction of air flow in or out is the downpipes.

This coincides with the large HP gains seen with larger diameter DPs, compared to small gains from exhaust and intake. Suspicion validated!

We hashed out the details for a couple weeks and the research was ridiculous. After everything checked out, and the parts arrived, it was time to find a shop that would / could give us what we wanted. I landed on G&M Express in Holland, MI. Kind of a hole in the wall shop to be perfectly honest; but they had all the answers I was looking for. 30+ years of combined pipe bending between the two installers (one of which was the owner, Glenn). They subscribed to the mantra: "bending pipe is art...and you can either draw good, or you can't"...also Glenn calls everyone "Papa". LOL

I made an appt. for this afternoon, and we got right to work. They were cool with me being very active in the bay with them to get everything just how I wanted it.

**DISCLAIMER**

Beyond discussing the details of this build with Spartn27, I have NO affiliation with MDesigns or G&M Express.

First step was cutting out the stock exhaust, right up to the downpipe flange. So, let's talk about what it is we're replacing:

On the left end you can see the flex pipe on the downpipes going into the flange. From there, dual 2.25" pipes enter and exit the third cat, and go straight into the resonator.

This is what the 3rd cat (left) and res (right) look like off the car:

Looking down into the inlet of the third cat. You can see the steel honeycomb (looks like a fine mesh) that runs the length of the cat (about 10").

Looking down through the outlet of the resonator...Much to my surprise, this looks like it's just a straight piece of solid 2.25" pipe (x2) that runs the length of the resonator. My guess is it decreases resonation through the sound-deadening properties of sheer mass alone (res body about 20" long).

The dual 2.25" pipes leave the resonator and travel back to double 90* bends

Then snake up to stock mufflers and 4" Chrome tips

Looking backwards through the OEM muffler outlet you can see it's straight pipe back to the front of the muffler, where there's a flat wall, and an opening. This tells us the OEM mufflers area chambered muffler...which I'm pretty sure is BAD for turbo's since it can create a shockwave that travels back to the turbo. Maybe less of an impact being that it's at the end of the road.

Now...on to what we put in it's place. Let's start with the front.

I had him leave the stock downpipe flanges in place for easy connections once I spring for EPP DPs.

First step was opening up about a 3" long piece of stock 2.25" pipe on the rear side of the OEM flange, to 2.5" ...x2. Then welded on 2x 2.5"-bends to widen the birth from the stock flanges, outwards.

The wider birth was needed to make the connections from the flange to the new resonator. The body is a 4"x9" oval, and is only 11" long.

Magnaflow Dual 2.5" straight through, in/out. NO-X.

Two more 2.5" bends coming out of the resonator, to reduce the birth narrower for the Y-Pipe...Yeah you heard me...Y-Pipe!

Magnaflow dual 2.5" into single 3" Y-Pipe. The purpose of reducing down to a single larger diameter pipe is to reduce surface area. Two 2.5" pipes have far greater surface area than a single 3". When you're talking laminar flow, surface area is bad. Not only does it create skim loss wherever the gasses drag across the surface, but also acts as a heat sink to cool the gasses, which makes them more dense, and again slows them down. By using a single large diameter pipe we're able to keep velocity up, friction down, and maximize the inside area of the pipe for better flow.

Not to mention all of the benefits of an X-Pipe; harmonizing exhaust gasses, etc.

Simple math would appear to give you more inside area with 2x 2.5" pipes than a single 3"...which is true...but with the added friction loss from smaller pipes, inside area is no longer the winning attribute in hyperphysics.

The single 3" pipe then travels back to where the original 2.25 pipes hit their 90's and enter another Y. This time it's backwards - Single 3" to dual 2.5"

Setup so far

From here, each 2.5" outlet is met with a single 2.5" dual 90* pipe, on an upward angle to each muffler.

...as such

Magnaflow mufflers are a similar straight through design to the resonator. Only difference being they have a slight bend in the center from offset in, center out. Same dimensions as the resonator; 4x9" Oval 11" long.

A small piece of 2.5" was welded in, to bridge to the tip

And the tips were welded in place.

2.5 to 4" Double wall stainless tips. These were originally chrome, but were professionally stripped and powder coated satin-black.

Ditto for the other side

It doesn't look like it because of the bend and the angle taking the pic from, but the center section of 3" is about 4.5' long.

Finishing touches and adding the final hangers to line up with OEM

Shot from front to back

After everything was welded in place, the entire system was coated in matte-black ceramic exhaust paint (mufflers, tips, and resonator excluded).

The result was unlike anything else currently offered for our platform. Rather than trying to make it sound like a big V8 (which is isn't), it makes it sound like what it is; a twin turbo charged, high performance, work of art.

There is ZERO buzz or rasp.

The exhaust note is VERY deep. It sounds like a 12" subwoofer just humming away.

From inside the cabin you can hear a quiet low tone that almost disappears with throttle. Cruising speed, the sound is noticeable, but not obnoxious and has no drone.

To be honest I was actually a little disappointed initially because it sounded so quiet, but after getting out and walking around the truck I noticed is has a different personality from outside the vehicle.

There really isn't any 'bubble' or 'camming' sound, it's very smooth and consistent (courtesy of our giant x-pipe (aka the 3")), the note is so smooth and deep you can feel it in your chest.

Volume is on the lower side, and overall pretty quiet with throttle.

When you let off the throttle from a rev it has a slight 'falling over itself' tone.

I'm terribly curious to hear the change once I start messing with downpipes and or intake.

No turbo whistle is audible, just like before....yet.

Butt-dyno on the way home felt like it pulled harder, but that's so subjective you'll have to take it for what it's worth.

Due to the exotic sound of this setup, I'm having a hard time providing anything remotely close to accurate with a sound-clip or video. It's just so low I cant find a mic to pic it up, but I'll play with that tomorrow too.

More follow-up and adjustments to come...but I teased you all enough throughout the day, I knew I had to get something posted! ;D

I got a decent video today, and some enlightening tinkering results!

[size=18pt]

First Video: Stock Exhaust.

Stock air box + K&N Panel Filter. No engine mods. No tune.

http://youtu.be/XhgJGxbDtsA

Second Video: A look under the XSport at the finished / installed MDesigns system from flange to second Y.

http://youtu.be/GBHfPDFuZR8

Third Video: MDesigns Exhaust Prototype

Stock air box + K&N Panel Filter. No engine mods. No tune.

http://youtu.be/y9wq6Zn83xM

As for the results of the tinkering:

I was curious where the restriction was, now that the exhaust was free'd up and I still couldn't hear any turbo noise over stock.

With an open airbox and no filter...no turbo sound.

Open downpipe flange...still no audible turbo noise.

Then both open downpipes and open intake. Still no change in turbo noise.

This leads me to believe the main restriction of air flow in or out is the downpipes.

This coincides with the large HP gains seen with larger diameter DPs, compared to small gains from exhaust and intake. Suspicion validated!