Next I moved on to upgrading the transmission. I did a ton of research to complete this conversion. I also created a trans swap thread on 3 popular corvette forums to share my work, and have over 40,000 views between them. I also received tons of comments and questions for information on taking on this conversion. There are a few different ways to go with the install, but this is the route I took with it.

Summer 2011 I picked up a T56 trans out of a 94' Trans Am that a guy was parting out. So I finally decided to go for the install and removed my old trans and clutch linkages and sold them. I kept my Centerforce dual friction clutch and Fidanza aluminum flywheel. I picked up a conversion kit from Weir Hot Rod Products to convert the trans from a pull type clutch to a push, so I can use my current clutch and flywheel. The kit comes with the following:

LT1 T56 Kit (converting the pull clutch to a more conventional push design)

356 T6 Cast Aluminum Heat Treated Bellhousing

Self Adjusting Hydraulic Release Bearing Assemble (which is rebuildable)

Steel Block Plate

Pressure Tubing

All Necessary Bolts

Master Cylinder

Clutch Line

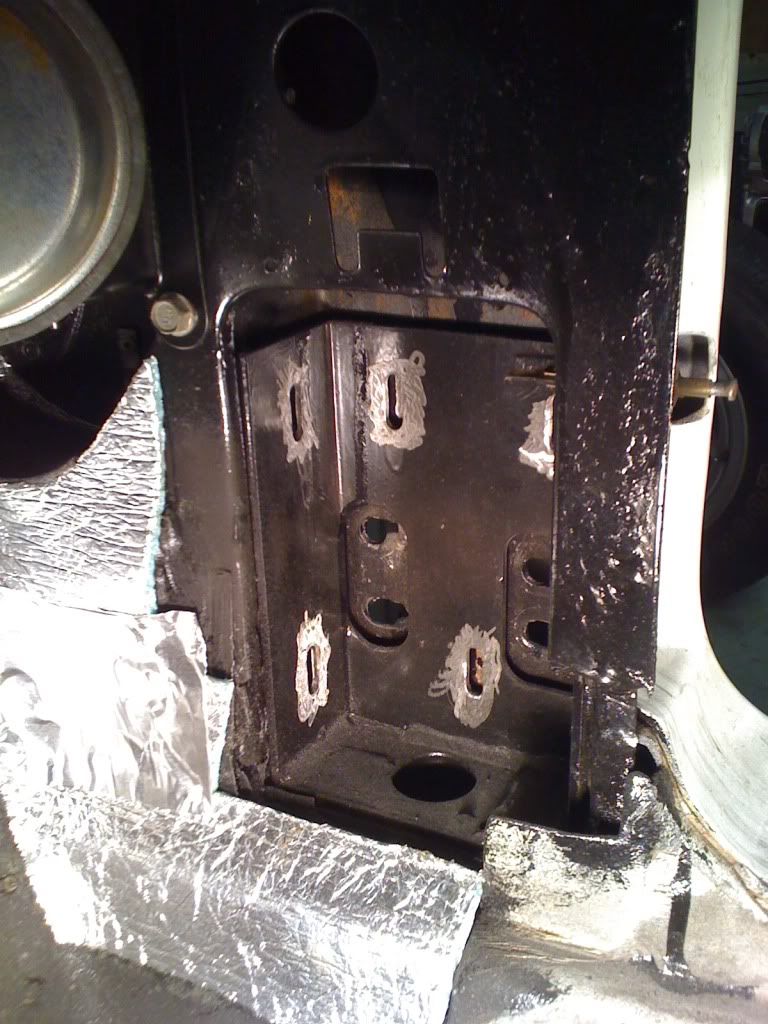

Cleaned up the trans and picked up a Hurst Billet Plus Shifter.

I checked to make sure the clearance for my hydraulic throw-out bearing was going to be within specs, 1/8" give or take a 1/32. I started out by bolting the block plate, flywheel, clutch disk, pressure plate, and bellhousing to the engine. I put a straight edge across the bellhousing to trans surface and used a tape measure to measure the distance from the clutch fingers to the straight edge which gave me 1 1/2".

Then I installed the hydraulic throw-out bearing to the trans and used a straight edge again to measure the distance from the bearing face to the trans to bellhousing surface, which gave me 1 3/8". According to my measurements, subtract the two, I have 1/8" clearance between my throw-out bearing and clutch fingers which is right in specs.

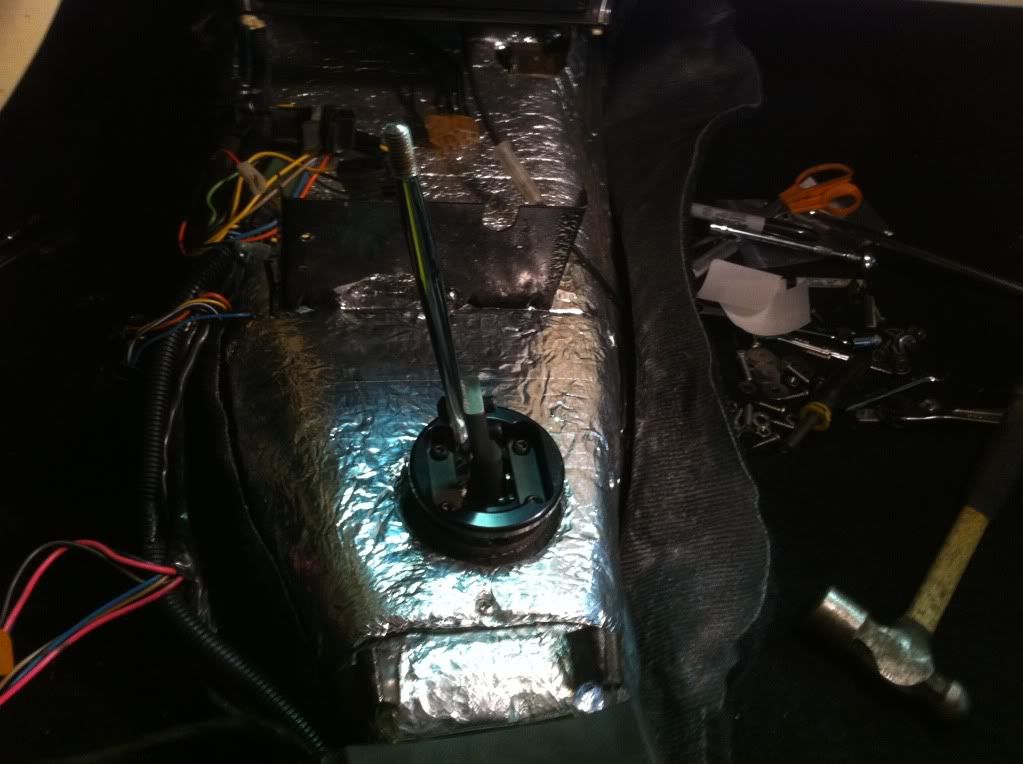

I insulated the tunnel to cut down on heat.

I relocated the battery cable so it is out of the way of the new shifter location and trimmed the tunnel up.

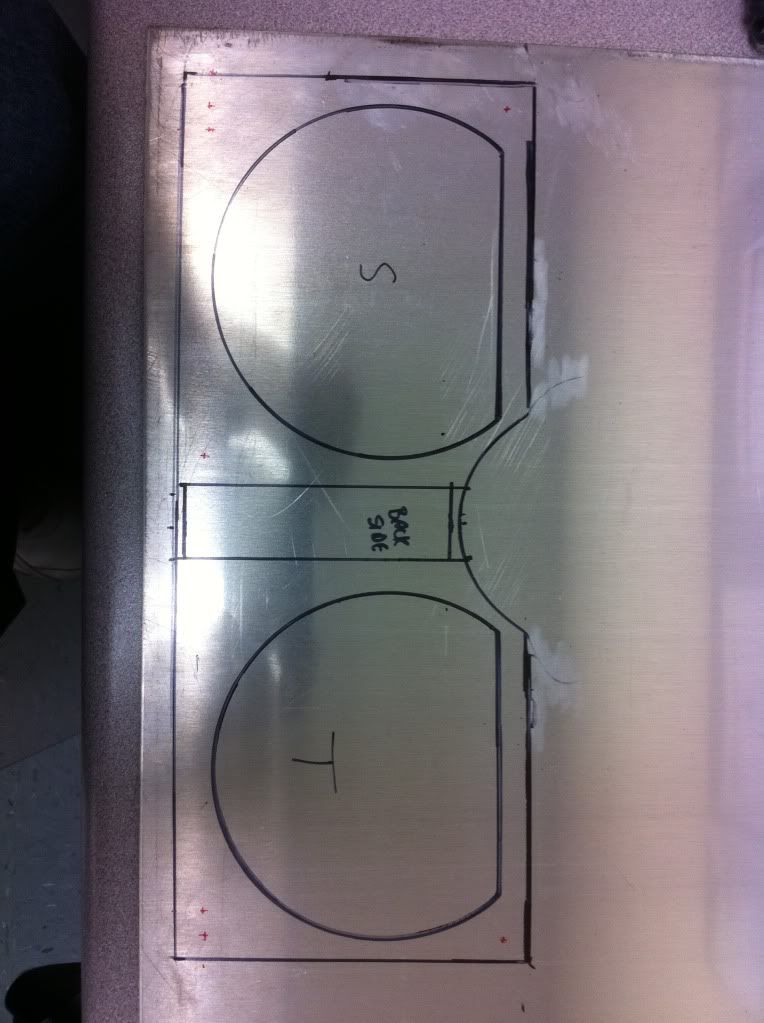

I made a removable cover for the tunnel with a neoprene seal on one side and insulation on the other.

Bought a driveshaft from an 82' vette, has the correct yoke that I need and had it shortened 1", installed solid Spicer U-Joints, and balanced. Now 24" from center u-joint to center u-joint.

I needed an angle adapter for the firewall to clutch master. I received this generous donation from Keisler.

I used a rod end and bolt coupler for the clutch pedal connection.

Installed the clutch master with remote reservoir.

Bolted up the trans.

Since the new trans uses an electronic speedometer, I made a filler plate and installed this 3 3/8" Autometer Digital Speedometer/ Tachommeter Combo.

Also, I picked up all the electrical plugs I needed for the trans speedometer, reverse lockout, and backup lights from ebay.

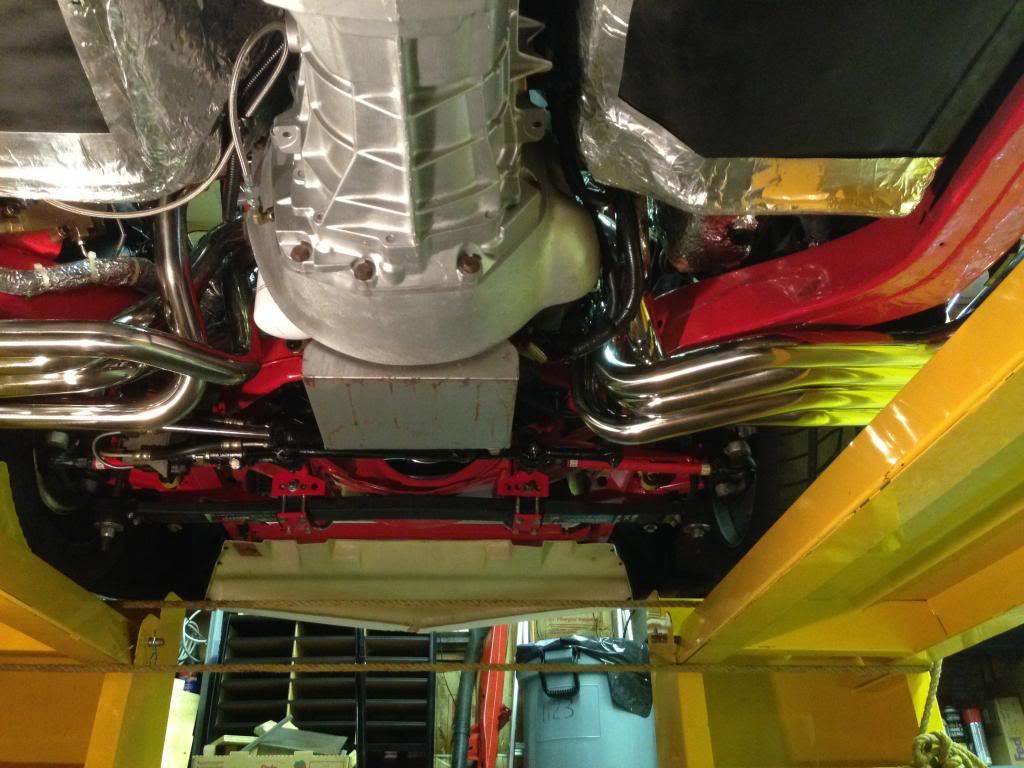

Here's a pic of the replacement BowTie Overdrives crossmember powdercoated Flame Red, the same color as my chassis.

Here's a couple pics of the undercarriage.

I had to shorten the emergency brake cable because the new crossmember positioned the cable pulley back further which added to much slack for adjustment.

Here is how to wire up the transmission sensors:

With OEM GM connectors;

Reverse Lockout

Pink - +12V (wired to power on with the brake lights at the brake pedal switch)

Green - Ground

Backup Lights (connected to the stock wiring to my 4 speed)

Green to Ignition +12V (stock blue wire)

Brown to Backup Lights (stock green wire)

VSS

Purple - Speedometer Signal

Green/Black - Ground

I took my truck out and marked off 2 miles from my house to calibrate the new speedometer in the vette. I took out the vette, calibrated the speedometer, and headed for the highway. The biggest things that I noticed the most was how much smoother shifting was. Definitely much better! Also with the stock trans in 4th gear at 60 mph my vette was at a very loud 3100 rpm. Now in 6th gear at 60 mph my vette is at a mellow 1550 rpm! This is just so much better than before.

A pic of the Autometer Digital Speedometer/ Tachometer installed.

Modified the shifter so it comes up through the stock console position. Here's a few pics.

A pic with the finishing touch of the shift pattern plate installed. My 6 speed swap is officially complete!

Here's some before and after pics of when I cleaned up the trans.

Before:

After:

Also, here's a couple pics of the stock T56 bellhousing (left side) next to the upgraded bellhousing (right side) that I installed.