I realize that the clean side separator is there and not the can. However both sides of the engine are trying to suck air from the same source at roughly the same vacuum (according to the install instructions just upstream of the turbo which is where the clean side is also tapped), that is my point. At least that is what I got from reading the install instructions. I might be wrong here but that's my understanding.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Ecoboost PCV issues

- Thread starter Tuner Boost

- Start date

Tuner Boost

New member

OK all.

As much as I respect most of what Livernoise does, and they are excellent in customer service, etc. This is an area that all Any told you is dead wrong, and here is why. (unless they used some can hooked up wrong...the RX system is the most advanced in crankcase evacuation on the market, but there are a ton of snake oil or wrongly designed cans out there)

So, point by point.

First let me start with my background. I have been doing this for over 40 years and started as a GM factory trained tech in 1974 and have seen most anything in the automotive world as changes in technology and major flops have come and gone. I also do design work that GM has implemented in their advancements in correcting PCV and oil ingestion issues. I do systems for everything from Ford to Ferrari, from classic Maserati's that were the first to implement oil separating cans on their LeMans cars to todays championship drag racing applications.

Myself or my drivers through the years have multiple Divisonal, National, and World Championships in several classes both NHRA & IHRA in stock, super stock, super gas, super comp, top dragster, quick rod, and were one of the dominate teams for years in the Eastern US Big$ Bracket series. I am also a graduate of the Reher Morrison Racing engine building school, and our systems are used exclusively by some of the most respected builders of turbo and supercharged performance builds from the famous Nickey Chicago signature builds (all come with a RX system installed) to IPS turbo charging, SNL, and many more.

We have in the past, and continue to be pioneers in many industry first's (first GM V6 DI top mount supercharger systems, etc.) and when it comes to direct injection and any form of crankcase evacuation, we are among the most respected in the industry.

This is what I have done for longer than many have been alive, and we win or loose in Professional drag racing far to often by thousandths of a second. What we have learned in this lifetime we apply to the real world, and the EcoBoost has serious issues, all caused by a flaw in the PCV system.

So lets start with ANY engine, port injected, carb, or DI. All you ever want in the combustion chamber is air and fuel, and any amount of oil whatsoever has a negative effect in several areas during the combustion process. First, oil does not burn well at all (except 2 stroke oil formulated to mix with gas and burn clean) with the most obvious is the carbon and soot deposits it leaves. It also reduces the usable octane of the fuel and causes detonation (spark knock and spark retard is visible to any tuner logging and engine under load). It also disrupts the burn pattern, and this is critical in the design of the combustion chamber and piston tops (especially in a DI engine). It also reduces the quench areas ability to transfer and absorb heat. Then the deposits left that build up on the piston tops and the exhaust ports reducing the volumetric efficiency that the engineers worked so hard to achieve.

Here is a DI piston and you can see how complex this design is compared to a port injected flat top piston to see just how critical the burn pattern and quench areas are:

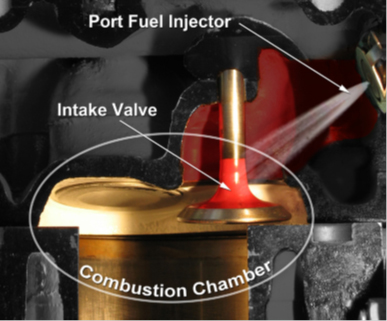

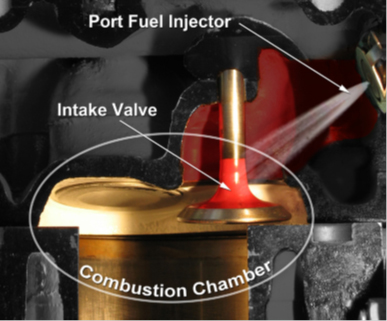

Now lets look at what could possibly be "lubricated" in the intake air charge system and the combustion chamber. There is nothing good about oil in the intake manifold, nothing to lubricate. The valves are lubricated by the oil that is delivered on the valve spring/camshaft/valve train side and there are carefully designed seals to prevent to much from entering. All of this is to an exact science the engineers that designed the engines have arrived at. The lower side of the valves are the tulip and the lower stem. No oil should ever be touching them as it bakes on and forms deposits. With a port injection engine, these deposits are prevented from forming due to the constant shower of fuel from the injectors washing off any of the PCV oil mist from the valves BEFORE it can bake on and form the hard abrasive deposits that are drawn up and wear the valve guides:

This keeps the intake valves clean and retains the shape of the valves and the ports so the engine can flow as designed with no obstructions or vortices created from deposits forming disrupting the complete intake port, valves, and pistons flow.

And that is where direct injection comes in, and the critical need to keep these deposits from forming. Here you can see with direct injection, the fuel can never touch the intake valve as the fuel is introduced directly into the combustion chamber:

Ans since the fuel is not injected (and it is at 1000-3000 PSI depending on the system vs 45-55 PSI for port injection) until the final 20% or so of the compression stroke, there can be no residual fuel brought back from the valve overlap reversion pulses.

This is an un-planned side effect of DI and it must be dealt with. Every auto maker in the world is scrambling to try different techniques, but to date, there is no solution that does not involve the end user draining and disposing of what is trapped.

So, where is any part of the engine benefiting from oil mist (and the sulfuric acid, water, unburnt fuel, and abrasive hydro carbon particles that are part of the PCV vapors)? Absolutely nothing but negative effects.

Now look at the crankcase. Watch this training video to understand what the PCV system does, why it does it, and the damage that an engine will sustain over time if the PCV system is not designed or functioning correctly:

https://www.youtube.com/watch?v=EPIfI9aZHt4

Now the Ecoboost has a serious design flaw that only allows evacuation during idle or low throttle. Anytime their is any boost present (app 80% of the operating time) the system closes, and all of these damaging compounds are accumulating and settling into the crankcase and mixing with the engine oil (gas in the oil, water in the oil, high rates of wear and oil contamination) until the crankcase pressure builds enough to force some of this out the clean (fresh) side inlet tube in to the drivers side turbo inlet. Since this is steam and hot gasses, when they hit the CAC (intercooler) they condense into the sludge and gunk that you see when removing the CAC to clean it. It also pushes this mix into the combustion chambers and it there is to much water at one time ingested, then hydro-lock occurs and catastrophic engine damage.

So, lets stop here and again, what part of any of the intake air charge system or any of the moving parts that the intake charge would touch. These are not the inefficient engines of the 50's and 60's, every single moving part will get proper lubrication, and exactly where it needs it, and any parts that should not have any oil on them will experience deposit formation from this build up.

Now lets look at what is in the PCV vapors that he claims are "lubricating" . Oil mist is only part of what makes up these vapors. Sulfuric acid does no metal parts good. Neither does water. The abrasive hard carbon particles certainly dont. Un burnt fuel has no lubricating properties, so this toxic mix could not properly lubricate anything any way, in fact just the opposite.

And further, this is only 15k miles on a Livernoise installed Magnasun supercharger intercooler w/out a proper catchcan installed. This oil has already baked on a residue that has insulated the cooler and reduced it's ability to transfer heat and cool the charge air as well as slowly clogging the fins preventing air from flowing at all eventually.

Then we come to another argument he posted in the past: This involved a claim that these vapors lubricated the top mount superchargers and was good for them. What part I ask? The bearings are all sealed, so no moving parts are touched that need lubrication, and depending on what type blower, most have a constant oil bath from the supercharger lubricant sealed into them. The rotors dont touch, unless oil residue builds up and causes interference and damage as they spin at extremely high rates and the clearance between them is minimal (some have a special coating on the leading edges that wear into each other for as close of tolerances as possible). Then, we have to look at the balance of the rotors. As they travel at such high speeds, 12-14,000 RPM plus, that when this oil residue builds up over time it throws off the balance and THEN we see bearing and shaft failure as well as damage/erosion to the rotors as the touch.

There are over 14,000 RX systems in use out there for over 12 years on every type application there is. If installed correctly, they all do exactly as advertised (as all the testimonials from all support).

Lets look at oil ingestion. The current DI engines still have nearly as bad of intake valve coking and valve guide wear as the early ones. Several patents by Ford, Audi, etc. have different valve timing events and other changes to try and reduce the coking, but to date none have been effective. The EB has such a large amount of water ingestion due to the flaw it actually helps reduce the rate the valves coke with deposits, but the damages caused by all this water in the crankcase, etc. far outweigh the benefits.

Now lets look at how DI engines have improved as far as intake valve coking.

Deposits such as this by 30-50k miles are still the norm:

And even in as little as 12k miles on this 2013:

We can see some progress has been made, but there is a long way to go.

We can see some progress has been made, but there is a long way to go.

And then there is the buildup of this residue in the ringlands of the pistons. As this builds up the rings stick and are unable to seal properly and excess blow by and oil consumption is the result. Stopping the ingestion can allow them to self-clean and free up again if the issue is not to severe. If it is to severe only a tear down and manual cleaning will correct this.

So, anyone with any questions, ask and be as specific as possible. None of this is opinion that I have posted here, this is all documented fact and reference material is plentiful. You cannot apply opinion and old wives tales to actual engineering and science. And plenty have post pictures of their own intake valves that they performed manual cleanings on to prove it (anyone can easily remove your own intake manifold and see first hand).

No auto maker admits to having the coking issue, yet they advertise how they are correcting it! yet the pictures from techs from all over the world show otherwise. From Audi adding back small port injectors, to GM stating their VVT valve events prevent ANY fuel from touching the valves, to Ford claiming they allow fuel to touch the valves (it does not). So all are scrambling to correct the issues

As much as I respect most of what Livernoise does, and they are excellent in customer service, etc. This is an area that all Any told you is dead wrong, and here is why. (unless they used some can hooked up wrong...the RX system is the most advanced in crankcase evacuation on the market, but there are a ton of snake oil or wrongly designed cans out there)

So, point by point.

First let me start with my background. I have been doing this for over 40 years and started as a GM factory trained tech in 1974 and have seen most anything in the automotive world as changes in technology and major flops have come and gone. I also do design work that GM has implemented in their advancements in correcting PCV and oil ingestion issues. I do systems for everything from Ford to Ferrari, from classic Maserati's that were the first to implement oil separating cans on their LeMans cars to todays championship drag racing applications.

Myself or my drivers through the years have multiple Divisonal, National, and World Championships in several classes both NHRA & IHRA in stock, super stock, super gas, super comp, top dragster, quick rod, and were one of the dominate teams for years in the Eastern US Big$ Bracket series. I am also a graduate of the Reher Morrison Racing engine building school, and our systems are used exclusively by some of the most respected builders of turbo and supercharged performance builds from the famous Nickey Chicago signature builds (all come with a RX system installed) to IPS turbo charging, SNL, and many more.

We have in the past, and continue to be pioneers in many industry first's (first GM V6 DI top mount supercharger systems, etc.) and when it comes to direct injection and any form of crankcase evacuation, we are among the most respected in the industry.

This is what I have done for longer than many have been alive, and we win or loose in Professional drag racing far to often by thousandths of a second. What we have learned in this lifetime we apply to the real world, and the EcoBoost has serious issues, all caused by a flaw in the PCV system.

So lets start with ANY engine, port injected, carb, or DI. All you ever want in the combustion chamber is air and fuel, and any amount of oil whatsoever has a negative effect in several areas during the combustion process. First, oil does not burn well at all (except 2 stroke oil formulated to mix with gas and burn clean) with the most obvious is the carbon and soot deposits it leaves. It also reduces the usable octane of the fuel and causes detonation (spark knock and spark retard is visible to any tuner logging and engine under load). It also disrupts the burn pattern, and this is critical in the design of the combustion chamber and piston tops (especially in a DI engine). It also reduces the quench areas ability to transfer and absorb heat. Then the deposits left that build up on the piston tops and the exhaust ports reducing the volumetric efficiency that the engineers worked so hard to achieve.

Here is a DI piston and you can see how complex this design is compared to a port injected flat top piston to see just how critical the burn pattern and quench areas are:

Now lets look at what could possibly be "lubricated" in the intake air charge system and the combustion chamber. There is nothing good about oil in the intake manifold, nothing to lubricate. The valves are lubricated by the oil that is delivered on the valve spring/camshaft/valve train side and there are carefully designed seals to prevent to much from entering. All of this is to an exact science the engineers that designed the engines have arrived at. The lower side of the valves are the tulip and the lower stem. No oil should ever be touching them as it bakes on and forms deposits. With a port injection engine, these deposits are prevented from forming due to the constant shower of fuel from the injectors washing off any of the PCV oil mist from the valves BEFORE it can bake on and form the hard abrasive deposits that are drawn up and wear the valve guides:

This keeps the intake valves clean and retains the shape of the valves and the ports so the engine can flow as designed with no obstructions or vortices created from deposits forming disrupting the complete intake port, valves, and pistons flow.

And that is where direct injection comes in, and the critical need to keep these deposits from forming. Here you can see with direct injection, the fuel can never touch the intake valve as the fuel is introduced directly into the combustion chamber:

Ans since the fuel is not injected (and it is at 1000-3000 PSI depending on the system vs 45-55 PSI for port injection) until the final 20% or so of the compression stroke, there can be no residual fuel brought back from the valve overlap reversion pulses.

This is an un-planned side effect of DI and it must be dealt with. Every auto maker in the world is scrambling to try different techniques, but to date, there is no solution that does not involve the end user draining and disposing of what is trapped.

So, where is any part of the engine benefiting from oil mist (and the sulfuric acid, water, unburnt fuel, and abrasive hydro carbon particles that are part of the PCV vapors)? Absolutely nothing but negative effects.

Now look at the crankcase. Watch this training video to understand what the PCV system does, why it does it, and the damage that an engine will sustain over time if the PCV system is not designed or functioning correctly:

https://www.youtube.com/watch?v=EPIfI9aZHt4

Now the Ecoboost has a serious design flaw that only allows evacuation during idle or low throttle. Anytime their is any boost present (app 80% of the operating time) the system closes, and all of these damaging compounds are accumulating and settling into the crankcase and mixing with the engine oil (gas in the oil, water in the oil, high rates of wear and oil contamination) until the crankcase pressure builds enough to force some of this out the clean (fresh) side inlet tube in to the drivers side turbo inlet. Since this is steam and hot gasses, when they hit the CAC (intercooler) they condense into the sludge and gunk that you see when removing the CAC to clean it. It also pushes this mix into the combustion chambers and it there is to much water at one time ingested, then hydro-lock occurs and catastrophic engine damage.

So, lets stop here and again, what part of any of the intake air charge system or any of the moving parts that the intake charge would touch. These are not the inefficient engines of the 50's and 60's, every single moving part will get proper lubrication, and exactly where it needs it, and any parts that should not have any oil on them will experience deposit formation from this build up.

Now lets look at what is in the PCV vapors that he claims are "lubricating" . Oil mist is only part of what makes up these vapors. Sulfuric acid does no metal parts good. Neither does water. The abrasive hard carbon particles certainly dont. Un burnt fuel has no lubricating properties, so this toxic mix could not properly lubricate anything any way, in fact just the opposite.

And further, this is only 15k miles on a Livernoise installed Magnasun supercharger intercooler w/out a proper catchcan installed. This oil has already baked on a residue that has insulated the cooler and reduced it's ability to transfer heat and cool the charge air as well as slowly clogging the fins preventing air from flowing at all eventually.

Then we come to another argument he posted in the past: This involved a claim that these vapors lubricated the top mount superchargers and was good for them. What part I ask? The bearings are all sealed, so no moving parts are touched that need lubrication, and depending on what type blower, most have a constant oil bath from the supercharger lubricant sealed into them. The rotors dont touch, unless oil residue builds up and causes interference and damage as they spin at extremely high rates and the clearance between them is minimal (some have a special coating on the leading edges that wear into each other for as close of tolerances as possible). Then, we have to look at the balance of the rotors. As they travel at such high speeds, 12-14,000 RPM plus, that when this oil residue builds up over time it throws off the balance and THEN we see bearing and shaft failure as well as damage/erosion to the rotors as the touch.

There are over 14,000 RX systems in use out there for over 12 years on every type application there is. If installed correctly, they all do exactly as advertised (as all the testimonials from all support).

Lets look at oil ingestion. The current DI engines still have nearly as bad of intake valve coking and valve guide wear as the early ones. Several patents by Ford, Audi, etc. have different valve timing events and other changes to try and reduce the coking, but to date none have been effective. The EB has such a large amount of water ingestion due to the flaw it actually helps reduce the rate the valves coke with deposits, but the damages caused by all this water in the crankcase, etc. far outweigh the benefits.

Now lets look at how DI engines have improved as far as intake valve coking.

Deposits such as this by 30-50k miles are still the norm:

And even in as little as 12k miles on this 2013:

And then there is the buildup of this residue in the ringlands of the pistons. As this builds up the rings stick and are unable to seal properly and excess blow by and oil consumption is the result. Stopping the ingestion can allow them to self-clean and free up again if the issue is not to severe. If it is to severe only a tear down and manual cleaning will correct this.

So, anyone with any questions, ask and be as specific as possible. None of this is opinion that I have posted here, this is all documented fact and reference material is plentiful. You cannot apply opinion and old wives tales to actual engineering and science. And plenty have post pictures of their own intake valves that they performed manual cleanings on to prove it (anyone can easily remove your own intake manifold and see first hand).

No auto maker admits to having the coking issue, yet they advertise how they are correcting it! yet the pictures from techs from all over the world show otherwise. From Audi adding back small port injectors, to GM stating their VVT valve events prevent ANY fuel from touching the valves, to Ford claiming they allow fuel to touch the valves (it does not). So all are scrambling to correct the issues

Tuner Boost

New member

To add to and clarify, the RX system uses the inlet side of the turbos for evacuation while in boost, and the checkvalves prevent any reversion or back flow. The cleanside tube is only on the drivers side, and the drill into this for evacuation underboost must be closer to the turbos. The pass side (or on a transverse the opposite side) turbo has not line tapped in to disperse suction, so it provides app 80% of the suction needed to evacuate properly. On the clean side, every inch closer to the turbo there is less dispersion from the air filter, a the actual vacuum measured increases. So the clean is almost always at less suction at that barb allowing the flow to maintain cleanside flushing air in, dirty foul vapors out the opposite side. When the brief transition from non-boost to boost occurs the flow can reverse momentarily, thus the cleanside separator to trap that oil and allow it to be drawn back in as soon as the flow is correct again, or we would just leave the OEM clean side intact.

Tuner Boost

New member

Here are a few more links to see just how this effects all manufacturers even today:

https://www.google.com/search?q=intake+valve+coking+deposits+with+direct+injection&hl=en&tbm=isch&source=lnms&sa=X&ei=ojZEU6iqK6O-0AGr54DYDQ&ved=0CAcQ_AUoAjgK&biw=1600&bih=775&dpr=1

This is a great one, but they are assuming the PCV system has no no ingestion issues, and is also taking the PR statements that all is now solved, which we as engine builders on these new GDI engines see first hand it is not. I wish the automakers could be honest instead of always down playing issues (see GM's latest lawsuits).

https://www.youtube.com/watch?v=IzXeeCiSL7k

https://www.youtube.com/watch?v=6n-F73rQZDo

https://www.youtube.com/watch?v=D-hQsL-FZWw

https://www.youtube.com/watch?v=bRiZOTTel34

And this shows an upper induction cleaning service can only do so much. Either clean manually, or prevent it from the beginning with the RX system:

https://www.youtube.com/watch?v=yuHxy2qdtC8

https://www.google.com/search?q=intake+valve+coking+deposits+with+direct+injection&hl=en&tbm=isch&source=lnms&sa=X&ei=ojZEU6iqK6O-0AGr54DYDQ&ved=0CAcQ_AUoAjgK&biw=1600&bih=775&dpr=1

This is a great one, but they are assuming the PCV system has no no ingestion issues, and is also taking the PR statements that all is now solved, which we as engine builders on these new GDI engines see first hand it is not. I wish the automakers could be honest instead of always down playing issues (see GM's latest lawsuits).

https://www.youtube.com/watch?v=IzXeeCiSL7k

https://www.youtube.com/watch?v=6n-F73rQZDo

https://www.youtube.com/watch?v=D-hQsL-FZWw

https://www.youtube.com/watch?v=bRiZOTTel34

And this shows an upper induction cleaning service can only do so much. Either clean manually, or prevent it from the beginning with the RX system:

https://www.youtube.com/watch?v=yuHxy2qdtC8

Has anyone thought about using a Racor CCV4500. Allot of us have one on my 6.0 and it works perfect. On the 6.0 you can suck about a quart of oil into the turbo through the CCV every 5000 miles.

We do not worry about water in the oil because oil temp cooled down to 200, when working hard the oil temp pre cooled is around 300.

We do not worry about water in the oil because oil temp cooled down to 200, when working hard the oil temp pre cooled is around 300.

Tracy I don't believe anyone is saying that you do no have lots on knowledge on this subject and stating that LMS is wrong is a bit much as they have as much experience on the EB cars and trucks as anyone. That said I am still interested in your product if just the clean side separator. I would like to get your input on my previous question on the different install locations between the SHO and the F150.

ShoBoat said:Tracy I don't believe anyone is saying that you do no have lots on knowledge on this subject and stating that LMS is wrong is a bit much as they have as much experience on the EB cars and trucks as anyone. That said I am still interested in your product if just the clean side separator. I would like to get your input on my previous question on the different install locations between the SHO and the F150.

Tracy has more than adequately backed his claims with FACTS .

Livernoise , to be deemed credible should as well .

bpd1151

Active member

Although I don't claim to be anywhere near as knowledgeable on this topic, as either TunerBoost, or reps from Livernois, I do find the points and counterpoints, to be if nothing else, just plain interesting and informative.

To TB......

I am perplexed as to why you keep posting information regarding LMS's Supercharger, and also continue referencing specifically GM related products and examples in both video form, as well as still picture form that don't apply to the Ecoboost platform?

The piston you displayed is not a Ford Ecoboost factory piston. What piston product is that culled from?

The Ecoboost powerplants have never employed Superchargers, and to generically state "DI engines" in a general sense, I think is perhaps glossing over, and broadly labeling all DI engines as being related to specific perceived problematic issues to the Ecoboost platform individually.

Also, I'm pretty confident, based on my own driving habits (and mind you, I tend to drive more aggressively, than most) that to say all Ecoboost engines are "in boost" 80% of the time, is also merely an opinion.

I myself am not anywhere near "in boost" at this high of a stated percentage, so perhaps the evacuation system employed in the Ecoboost engines is operating more efficiently, more often, even in closed format?

Do you have any specific experiences related directly to the Ecoboost platform, including, but not limited to, actual teardowns of an Ecoboost engine, and it's related internals, and not just GM products?

Finally, can you render any opinions, or thought processes to those members here who are using Methanol (whether in 100% solution, or a lesser dilution) as to whether or not it's use is providing the "cleaning" abilities as currently believed, in lieu of running any type of catch can product?

Also curious if you have either spoken directly with, or exchanged any type of electronic communication with EBPF member PainterPatt and inquire as to why he has posted his experiences thus far with your product having caught zero oil deposits/contaminants/etc. after more than 500 miles of use?

Thanks in advance for your time! :thankyou:

To TB......

I am perplexed as to why you keep posting information regarding LMS's Supercharger, and also continue referencing specifically GM related products and examples in both video form, as well as still picture form that don't apply to the Ecoboost platform?

The piston you displayed is not a Ford Ecoboost factory piston. What piston product is that culled from?

The Ecoboost powerplants have never employed Superchargers, and to generically state "DI engines" in a general sense, I think is perhaps glossing over, and broadly labeling all DI engines as being related to specific perceived problematic issues to the Ecoboost platform individually.

Also, I'm pretty confident, based on my own driving habits (and mind you, I tend to drive more aggressively, than most) that to say all Ecoboost engines are "in boost" 80% of the time, is also merely an opinion.

I myself am not anywhere near "in boost" at this high of a stated percentage, so perhaps the evacuation system employed in the Ecoboost engines is operating more efficiently, more often, even in closed format?

Do you have any specific experiences related directly to the Ecoboost platform, including, but not limited to, actual teardowns of an Ecoboost engine, and it's related internals, and not just GM products?

Finally, can you render any opinions, or thought processes to those members here who are using Methanol (whether in 100% solution, or a lesser dilution) as to whether or not it's use is providing the "cleaning" abilities as currently believed, in lieu of running any type of catch can product?

Also curious if you have either spoken directly with, or exchanged any type of electronic communication with EBPF member PainterPatt and inquire as to why he has posted his experiences thus far with your product having caught zero oil deposits/contaminants/etc. after more than 500 miles of use?

Thanks in advance for your time! :thankyou:

SRT82ECOBOOST

New member

I think Livernois Motorsports (LM) clearly stated on where they stand concerning the use of a catch can and RX takes a completely different stance. LM says there is not a use for one and RX says for you to install one. LM is trying to give you free guidance on a product they don't sell and RX is trying to convince you to buy their product. Completely different motives from either side of this topic.SwampRat said:ShoBoat said:Tracy I don't believe anyone is saying that you do no have lots on knowledge on this subject and stating that LMS is wrong is a bit much as they have as much experience on the EB cars and trucks as anyone. That said I am still interested in your product if just the clean side separator. I would like to get your input on my previous question on the different install locations between the SHO and the F150.

Tracy has more than adequately backed his claims with FACTS .

Livernoise , to be deemed credible should as well .

Basically I don't think it is LM's responsibility to refute or agree with every other manufacturer's products claims when they do not represent the product.

^^ well said.

If we are taking facts, take 2 identical 3.5 EBs one with and one with out the RX or whatever catch can. Run them for 50k miles with the same maintenance schedule. Then tear them down and compare them that would be fact. Not some pics of different extreme cases and one video of some guy dumping some crud from a can (most of which didn't seem to be oil). As stated most of the pictures and related material is not from the Ecoboost platform.

fact or fiction? EB torture test tear down? I don't see a catch can on this one.

http://m.youtube.com/watch?v=BFfRcwesqNg

If we are taking facts, take 2 identical 3.5 EBs one with and one with out the RX or whatever catch can. Run them for 50k miles with the same maintenance schedule. Then tear them down and compare them that would be fact. Not some pics of different extreme cases and one video of some guy dumping some crud from a can (most of which didn't seem to be oil). As stated most of the pictures and related material is not from the Ecoboost platform.

fact or fiction? EB torture test tear down? I don't see a catch can on this one.

http://m.youtube.com/watch?v=BFfRcwesqNg

More valid points being being brought up that need to be addressed .

Why after 500 plus miles was painterpats RX bone dry as he stated ... I forgot I brought that up earlier .

What about the mounting choices that may make an impact on how much contaminate is caught in the actual canister , this does make some sense .

I still believe that the reason that this issue was stired up is do to Livernois saying to a member not to use any type of OCC .

No one is saying Livernois HAS to address us as to there reasoning but according to ShoBoat .... he said they will . So what gives ......

I just think it would be in Livernois's best interest to inform us as to there reasoning behind this .

If they can provide a valid reason I will not use MY RX .

Why after 500 plus miles was painterpats RX bone dry as he stated ... I forgot I brought that up earlier .

What about the mounting choices that may make an impact on how much contaminate is caught in the actual canister , this does make some sense .

I still believe that the reason that this issue was stired up is do to Livernois saying to a member not to use any type of OCC .

No one is saying Livernois HAS to address us as to there reasoning but according to ShoBoat .... he said they will . So what gives ......

I just think it would be in Livernois's best interest to inform us as to there reasoning behind this .

If they can provide a valid reason I will not use MY RX .

This is a sensible and scientific approach, and I have stated before in the past, provide the data for objective comparison. I too am curious about the methanol-"clean valves/intake" connection and would like a scientific discussion on that. References, please, if you will.ShoBoat said:If we are taking facts, take 2 identical 3.5 EBs one with and one with out the RX or whatever catch can. Run them for 50k miles with the same maintenance schedule. Then tear them down and compare them that would be fact.

Livernois does not have to state their opinion publicly, and we are awaiting their direct input on this topic if they so choose. But until they provide objective data, we have only the battle of opinions to consider.

One thing to remember: no one vendor is infallible and no one vendor is THE source for all information. Otherwise there would be no need for feedback, no need for correction, and no need for invention. The focus needs to be on getting objective data, and sometimes that means being the guinea pig (painterpatt in this case)! And even that may not be statistically representative without a large enough sample.

Tuner Boost

New member

sho, any location you can mount is fine...but the water will be there any time a crankcase is not evacuating it in small steady amounts as soon as it enters.

The cooler, the better as both coalescing and condensation is used to separate these compounds.

The cleanside separator will do you no good without correcting the lack of evacuation......you must correct that (and a Ford dealer in the midwest with a 2013 that has had every TSB done and is still experiencing the issues has approval to install and test the RX system and monitor it's effectiveness, so watch for the results. It will be a long term test so I will report what I can as I get results from them).

bpd, you can easily test and see that the EB makes boost anytime your cruising. It is part of what makes this engine so powerful and responsive. The small turbos begin spooling up as soon as the throttle is opened. You can also put a flow gauge inline between the intake manifold vacuum port and the PCV valve that is integrated into the passenger side cam cover. You will see strong flow at idle only. Any time other than very light throttle, the flow ceases and thus the evacuation.

As to my qualifications and experience vs Livernoise, I dont question anything else they do, and do well. But I backed up all with easily verifiable facts and documentation. And yes, I show pictures from several makes of direct injection engines as well as actual EB engines. Since part of the issues the EB experiances are direct injection as a whole related, it is relevant to the discussion. Thats why I provided so much back up material to reference. The only thing the EB has different is the flaw in the PCV design, and with over 250 EB systems installed and in use over the past 3 months, every single end user has reported (the ones that have left feedback) all the issues have gone away.

The supercharger story is also directly related to their nit understanding proper crankcase evacuation and the issues related to it, and they are hardly alone. Most big known shops do not understand it...it is not taught anywhere any more so most just make assumptions. Look at LMR that is well known and respected. They delete the entire PCV system and allow all of these compounds to accumulate in the crankcase and just relive pressure. The example I gave with the top mount SC's is an example of that. One must first understand all the functions of the PCV system and all that it does. And I still want anyone here to tell me what this mix of gunk can do to help any part of an engine. This is the ONLY area we really disagree on, and they have never in the 4 years since we began this debate have ever given any actual examples other than opinions. I have a ton of respect for them in every other area. Now I will point out one more thing. With a lifetime of Championship (not going to a test and tune day) drag racing, we experience what most never do. You can still find one of our team/family at most every NHRA National event, and our experience with proper crankcase evacuation is shared with every winning team out there. All constantly evacuate the crankcase to save these engines and anyone at a race simply needs to walk through the pits and stop at any teams area and see in person. An these we change oil after every event. On the street, with extended oil change intervals, this is even more critical.

Weekend before last, Peter won both Stock and Super Stock, and this weekend we had 6,900 plus runs down LVMS breaking all records of the history of the track as far as race cars down the track, and next month is Bristol (the family puts on the most driver attended drag races in history):

The picture I showed of the piston is pour forged version. Here is the stock EB piston:

Not much difference in the top design.

And more ecoboost specific pictures:

Each above is a different EB engine with as little as 30k miles, and the most was at 70k miles. Then after manual cleaning:

Below is an actual EB CAC:

From the shop EB truck showing as the liquids separate:

And finally,

if all we cared about was sales, we would just offer a can like everyone else and not design the complete systems that correct any shortcomings, and would not go into the intense technical details of all this...we would just sit back and sell cans. There is not a singe company in the world that does the R&D we do on such a wide variety of platforms. We purchase every can we see on the market, run the same tests, and dissect them for all to see.

And, Racor, Alfa Laval, etc. all have great systems....but for pretty pricey solutions. And all would have to be modified to correct the EB's flawed PCV system.

Look at all the oil analysis results of the EB's showing high levels of fuel. water, metals from wear.

And then the Ford endurance test. Watch the video. of the tear down. They never show the intake valves...only the underside of the cylinder heads up close. The EB engine is amazing, one of the best DI engines to date, but the PCV system flaw is not the engineers that designed the engines fault, those decisions are made by accounting, legal, and management that look at the bottom line only.

I am not here to force this on anyone. You buy your vehicles, and YOU decide how to care for them. If your fine with this gunk being ingested, 99% plus of the owners today never know it and are happy, so dont change a thing. This is only for those wanting to learn more and to better care for their engines.

We have been building turbo and supercharging systems for direct injection V6's for longer than the EB has been in production, and learn a ton by experience...were sharing that experience here with those that do want to learn...but we are not here to fight or have arguments about who is the "best"....only to share, provide actual verifiable facts, and give the resources to search and learn for your self.

Anyone can verify all I have claimed here, on your own vehicle easy enough.

And again, Livernoise is one of the best one stop shops in the US and does mods and tuning for many different brands as well. I send them non stop referral business and if I didn't believe they were among the best, I certainly would not continue doing so. They have one of the best equipped facilities in the country as well. I endorse them and trust in most all they do. This is the only area where we have disagreed and watch, I expect when it comes to the ecoboost they will come around as it has such severe issues with the PCV system.

So again, not here to fight, I don't compete in anyway with Livernoise, and those that follow us know we also endorse direct competitors that also have effective functioning catchcans, and that certainly gains us noting in sales, just the opposite.

The cooler, the better as both coalescing and condensation is used to separate these compounds.

The cleanside separator will do you no good without correcting the lack of evacuation......you must correct that (and a Ford dealer in the midwest with a 2013 that has had every TSB done and is still experiencing the issues has approval to install and test the RX system and monitor it's effectiveness, so watch for the results. It will be a long term test so I will report what I can as I get results from them).

bpd, you can easily test and see that the EB makes boost anytime your cruising. It is part of what makes this engine so powerful and responsive. The small turbos begin spooling up as soon as the throttle is opened. You can also put a flow gauge inline between the intake manifold vacuum port and the PCV valve that is integrated into the passenger side cam cover. You will see strong flow at idle only. Any time other than very light throttle, the flow ceases and thus the evacuation.

As to my qualifications and experience vs Livernoise, I dont question anything else they do, and do well. But I backed up all with easily verifiable facts and documentation. And yes, I show pictures from several makes of direct injection engines as well as actual EB engines. Since part of the issues the EB experiances are direct injection as a whole related, it is relevant to the discussion. Thats why I provided so much back up material to reference. The only thing the EB has different is the flaw in the PCV design, and with over 250 EB systems installed and in use over the past 3 months, every single end user has reported (the ones that have left feedback) all the issues have gone away.

The supercharger story is also directly related to their nit understanding proper crankcase evacuation and the issues related to it, and they are hardly alone. Most big known shops do not understand it...it is not taught anywhere any more so most just make assumptions. Look at LMR that is well known and respected. They delete the entire PCV system and allow all of these compounds to accumulate in the crankcase and just relive pressure. The example I gave with the top mount SC's is an example of that. One must first understand all the functions of the PCV system and all that it does. And I still want anyone here to tell me what this mix of gunk can do to help any part of an engine. This is the ONLY area we really disagree on, and they have never in the 4 years since we began this debate have ever given any actual examples other than opinions. I have a ton of respect for them in every other area. Now I will point out one more thing. With a lifetime of Championship (not going to a test and tune day) drag racing, we experience what most never do. You can still find one of our team/family at most every NHRA National event, and our experience with proper crankcase evacuation is shared with every winning team out there. All constantly evacuate the crankcase to save these engines and anyone at a race simply needs to walk through the pits and stop at any teams area and see in person. An these we change oil after every event. On the street, with extended oil change intervals, this is even more critical.

Weekend before last, Peter won both Stock and Super Stock, and this weekend we had 6,900 plus runs down LVMS breaking all records of the history of the track as far as race cars down the track, and next month is Bristol (the family puts on the most driver attended drag races in history):

The picture I showed of the piston is pour forged version. Here is the stock EB piston:

Not much difference in the top design.

And more ecoboost specific pictures:

Each above is a different EB engine with as little as 30k miles, and the most was at 70k miles. Then after manual cleaning:

Below is an actual EB CAC:

From the shop EB truck showing as the liquids separate:

And finally,

if all we cared about was sales, we would just offer a can like everyone else and not design the complete systems that correct any shortcomings, and would not go into the intense technical details of all this...we would just sit back and sell cans. There is not a singe company in the world that does the R&D we do on such a wide variety of platforms. We purchase every can we see on the market, run the same tests, and dissect them for all to see.

And, Racor, Alfa Laval, etc. all have great systems....but for pretty pricey solutions. And all would have to be modified to correct the EB's flawed PCV system.

Look at all the oil analysis results of the EB's showing high levels of fuel. water, metals from wear.

And then the Ford endurance test. Watch the video. of the tear down. They never show the intake valves...only the underside of the cylinder heads up close. The EB engine is amazing, one of the best DI engines to date, but the PCV system flaw is not the engineers that designed the engines fault, those decisions are made by accounting, legal, and management that look at the bottom line only.

I am not here to force this on anyone. You buy your vehicles, and YOU decide how to care for them. If your fine with this gunk being ingested, 99% plus of the owners today never know it and are happy, so dont change a thing. This is only for those wanting to learn more and to better care for their engines.

We have been building turbo and supercharging systems for direct injection V6's for longer than the EB has been in production, and learn a ton by experience...were sharing that experience here with those that do want to learn...but we are not here to fight or have arguments about who is the "best"....only to share, provide actual verifiable facts, and give the resources to search and learn for your self.

Anyone can verify all I have claimed here, on your own vehicle easy enough.

And again, Livernoise is one of the best one stop shops in the US and does mods and tuning for many different brands as well. I send them non stop referral business and if I didn't believe they were among the best, I certainly would not continue doing so. They have one of the best equipped facilities in the country as well. I endorse them and trust in most all they do. This is the only area where we have disagreed and watch, I expect when it comes to the ecoboost they will come around as it has such severe issues with the PCV system.

So again, not here to fight, I don't compete in anyway with Livernoise, and those that follow us know we also endorse direct competitors that also have effective functioning catchcans, and that certainly gains us noting in sales, just the opposite.

Tuner Boost

New member

Painterpat, if you read this stop in so we can look at your install again and see whats up. 500 miles should show some caught.

TIA, painterpatt! Hope you can get RX to check out the catchcan status soon

Tracy, do you think methanol injection (in the air intake) is serving the function that fuel previously served in MPI engines? Cleaning gunk off the valves continuously while the engine is running?

Tracy, do you think methanol injection (in the air intake) is serving the function that fuel previously served in MPI engines? Cleaning gunk off the valves continuously while the engine is running?

Tracy, I respect you for defending your point of view. And I understand most of the reasons of the why. I am curios as to the issue with the Painterpat, if I order the complete system I would want to ensure that it works on the SHO not just the F150. Please let us know what you find.

Tuner Boost

New member

In the Meth Injection equipped engines we look at we see very little valve coking, and I attribute this to the meth/water injection cleaning and keeping further deposits from forming, so yes. Even some GM ones that should show heavy deposits have very little backing this up.

Sho, fully understand & I would feel the same way as well.

Here is one of the posts from a EB owner that had the excess fuel in the oil issues. The RX system collected nearly all of the gas so he could document the issue with Ford (they claimed it was normal) and they were finally able to fix his issues (I believe it was a leaking HPDI pump):

I suppose it really depends on what you want/expect from it. From Ford, every DI engine will have some light fuel in the oil and the FI group will have more. Does the catch can get it all out? no. Does it get a lot out, yes. I drain mine every few days now and I always have oil and fuel in the can. If it is in the can then it is not in the intake. That i can attest.

What it does NOT do is prevent/stop the issue with fuel getting into the oil that causes the oil level to rise. This is fixed, supposidly, by the TSB 14-0440 (i think it was). When mine was dropping in fuel in the oil super fast the can could not fix it..... but it was pulling out a ton from being bypassed.

I'm very happy with mine and its performance, but I have no delusions about what it is capable of doing.

We need Painterpat back in here to see whats up with his though ASAP.

Sho, fully understand & I would feel the same way as well.

Here is one of the posts from a EB owner that had the excess fuel in the oil issues. The RX system collected nearly all of the gas so he could document the issue with Ford (they claimed it was normal) and they were finally able to fix his issues (I believe it was a leaking HPDI pump):

I suppose it really depends on what you want/expect from it. From Ford, every DI engine will have some light fuel in the oil and the FI group will have more. Does the catch can get it all out? no. Does it get a lot out, yes. I drain mine every few days now and I always have oil and fuel in the can. If it is in the can then it is not in the intake. That i can attest.

What it does NOT do is prevent/stop the issue with fuel getting into the oil that causes the oil level to rise. This is fixed, supposidly, by the TSB 14-0440 (i think it was). When mine was dropping in fuel in the oil super fast the can could not fix it..... but it was pulling out a ton from being bypassed.

I'm very happy with mine and its performance, but I have no delusions about what it is capable of doing.

We need Painterpat back in here to see whats up with his though ASAP.

Tuner Boost

New member

Here is another with a recent oil analysis:

Hi everybody, I've been away for few weeks... work related! Anyway, just to let you know. I had the new updated service bulletin done, the block heater in a different location, new PCV valve and everything... Surprisingly, my oil level went down! The service manager check himself the oil level before my truck leave the shop. He told me that the oil level was right at the hatch marks!!! Now it's down a 1/4" below that... I still notice, gas smell if I remove the oil filler cap though.

On another note, I had an oil analysis done before I went to the dealership, just to cover my ass in case of engine failure and Ford would like to give me a hard time! It reveals a severe concentration of gas. The critical limit is 3% Vol and the analysis reveal the oil was over 5% Vol... My oil only had 1362 KM since the last oil change.... So Ford if you want to "Go Further" with your wonderfull Ecoboost engine, just fixed the problem at the source instead of trying to band aid the problem. Oil dilution like that, I see big mechanical problems in a near future, let me tell you!!! I have an extended warranty for 7 years but, is the problems going to stop at one point... Anyway, sorry for my long story. Anyone have any new development, please all let us know!

He has NOT installed the RX system.

Hi everybody, I've been away for few weeks... work related! Anyway, just to let you know. I had the new updated service bulletin done, the block heater in a different location, new PCV valve and everything... Surprisingly, my oil level went down! The service manager check himself the oil level before my truck leave the shop. He told me that the oil level was right at the hatch marks!!! Now it's down a 1/4" below that... I still notice, gas smell if I remove the oil filler cap though.

On another note, I had an oil analysis done before I went to the dealership, just to cover my ass in case of engine failure and Ford would like to give me a hard time! It reveals a severe concentration of gas. The critical limit is 3% Vol and the analysis reveal the oil was over 5% Vol... My oil only had 1362 KM since the last oil change.... So Ford if you want to "Go Further" with your wonderfull Ecoboost engine, just fixed the problem at the source instead of trying to band aid the problem. Oil dilution like that, I see big mechanical problems in a near future, let me tell you!!! I have an extended warranty for 7 years but, is the problems going to stop at one point... Anyway, sorry for my long story. Anyone have any new development, please all let us know!

He has NOT installed the RX system.

So if I read this right, all we need to do to avoid the build up is install a meth system? Why didn't you say so, I am marching over to my dealer right now and demanding that they install a meth system on my car right away! While we are at it we should petition ford to install them on all their EB's. What's not to like lots of powa and a clean engine! How can they refuse?

I think the problem with the intake/valves is "solved" with methanol, but the problem of those unwanted vapors elsewhere in the system, including the combustion chamber, still has to be addressed. Probably will get more breathing room with meth installed, though.

Similar threads

- Replies

- 1

- Views

- 296

- Replies

- 6

- Views

- 3K