BiGMaC said:

SHOdded said:

Problem is you have a GDI engine, and a TC one at that. So any cleaner you add to the fuel only gets to the injectors and the combustion chamber. You miss cleaning the intake tract, the intake valves, the turbo system, you get the picture.

Point well taken Manu :beer2: ... No fuel additive cleans the turbos, CAC and TB, ....but there are some gains/cleaning of all components in direct contact with the combustion chamber with BG44 documented in the BG testing over a 61K time period in a 2011 SHO including the intake valves :thumb: ... It's here:

http://www.bgprod.com/bgfueltest/ and dyno evidence of restored HP and TQ... Just as FYI

On todays DI engines there is actually zero effect from BG (which I like and use in Port injection engines) as no where in the entire fuel and combustion chamber does it ever contact any area but the piston tops to prevent any of this. Even though they did the most long term test, it is physically impossible for it to even keep injectors clean as they are operating at 2,000 plus PSI vs the old 45-55 PSI when the injectors would build up deposits over time. What they DID improve was doing an upper induction cleaning to help and that will result in removing some of the deposits resulting in increased power.....but that is dealing with the issue AFTER the deposits form. Best to prevent them from the start, and only a can that stops all the oil mist and gunk can do that. A JLT or other can WILL help slow the formation, so never a waste to use a can that only catches part of the mix....but only a can that catches all will prevent it, and we have the RX challenge open to any can on the market.

Here are good illustrations showing:

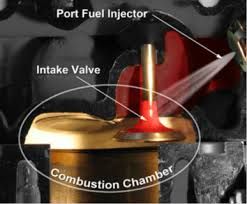

This is a port injection system showing how the valves were constantly showered with fuel spray from the injector, and top tier fuels (shell, mobil, etc. ) with detergent additives and other cleaners added to the fuel tank:

And here is direct injection. As you can see, no top tier fuel, no additive will ever touch the valves:

And further, here are pictures of a LS1 head from a 98 vette with 140k miles on it and just look, not a spec of deposits anywhere the fuel spray made contact:

Now here is a 2014 DI engine with 3200 miles on it...look close, the deposits are already forming, and the valve stem on the pic with it open shows the abrasive particles already begining to cause wear (and the guide will wear many times faster due to the material and hardness):

Now, using an upper induction cleaning is fine a few times, but be aware that every time these hard deposits are broken loose some are forced between the piston and cylinder wall causing scouring (scratches) and that is NOT good, so use a BG or SeaFoam rarely.