Ok, here is what I got from Julio as far as tuning it...

Here is a picture of the controller adjustment knobs... credit BPD1511 for this picture as I am too lazy to go take my own...

There is a "Turn On" and "Initial" rheostat. The "Turn On" rheostat is queued off the MAP sensor via voltage. You are supposed to use a voltmeter on the rheostat soldered end while on a dyno (or have a friend ride shotgun doing it for you...) or using the test button on the controller to set at which KPA(voltage) the pump kicks on..

Quote from Julio... and I verified he is correct via datalogs...

"Typically most 3 bar map sensors will move from 1.6 volts at zero psi to 4.8 volts at 30 psi

That's about .1 volt per psi boost. So 4 psi is 2.0 volts or close enough

The Turnon knob has a solder spot on its 12 o'clock position. Put a D.C. Voltmeter red lead at 12 o'clock and black lead ground, adjust for 2.0 and it's set to 4 psi"

That is how to set when the pump turns on...

There are two other adjustments that need to be made.. There is the "Initial" Rheostat sets the prelim ramp from start to finish... and then there is this... (Again... too lazy to take my own pictures.. credit this one to BPD1151)

This controller has the gain setings which dictates how fast/how much the meth ramps up while you are spraying or slope... I asked Julio if there was a best practice for this and here is his response..

"Initial and Gain play with each other and have a direct correlation to battery voltage on vehicle. Simply said adjust for no knock activity"

He gives an analogy in the instructions he sent..

"Simplest analogy is a bicycle ramp. You put 1 block on the front and 3 blocks on the back. Increasing initial is like adding 3 blocks to both front and back of ramp..same angle. Increasing gain is like 1 block added to the front and 4 to the back of the ramp, making it more aggressive. The length of your ramp is simply the turn on point vs max signal. So if you start at 8 psi and run 20 psi... thats 12 psi of increse. If you moved "turnon" from 8 psi to 12 psi, now you would have the same meth at 24 than you had at 20.... moved 4 psi. Make Sense? So if you run 20 psi boost, and you activate at 8... if you move your turnon to 10 and stay at teh same boost, you'll put in less meth since your ramp is only 10 psi long vs 12 it was before. To offset the shorter ramp, simply move the Gain up to compensate."

also

"I like to set my turn on point at 25-33% of the boost run. So 20 psi boost..I like 7 PSI. I like to see Gain settings no less than 5 as it can make the system lazy waking up. Initial I like to see no less than 11:45-12:00.. same lazy syndrome."

He also goes on to state...

"Dont worry about IAT..worry about knock. I have never seen a datalog on a fast car that the IAT stays flat. They all climb. Its just that it climbs less with the meth"

So how did I set it up you might ask? Simply put... I have configured it on LMS's tune and Brads tune... for me it takes about 20 minutes or so using my laptop to datalog through my SCT x4 so I can view real time feeds to make the adjustments... Do a couple slow accelerations while the boost building and monitor the LEDS that came with the Alky kit.. when it hits green I make a note of which KPA it kicked on at.. now I know when it kicks on...

Then I like to do a 3rd gear pull.. I monitor knock, AFR, and STFT... the STFT lets me know how much I am spraying throughout the run...and if I need to make any adjustments based on knock... If my trims are pulling a TON of fuel during the inital kick on the Meth, I adjust the initial back as long as I don't have any knock...

once I get that done, I monitor the rest of the pull for knock and adjust gain accordingly.. once I can get several runs in in where there is no KR then I am done adjusting the kit. My STFT's tell me how much fuel I am offsetting with Methanol... The idea is to just spray enough to stop the knock retard and no more... if you are spraying more than you need, then you are potentially hurting power production from running too rich...

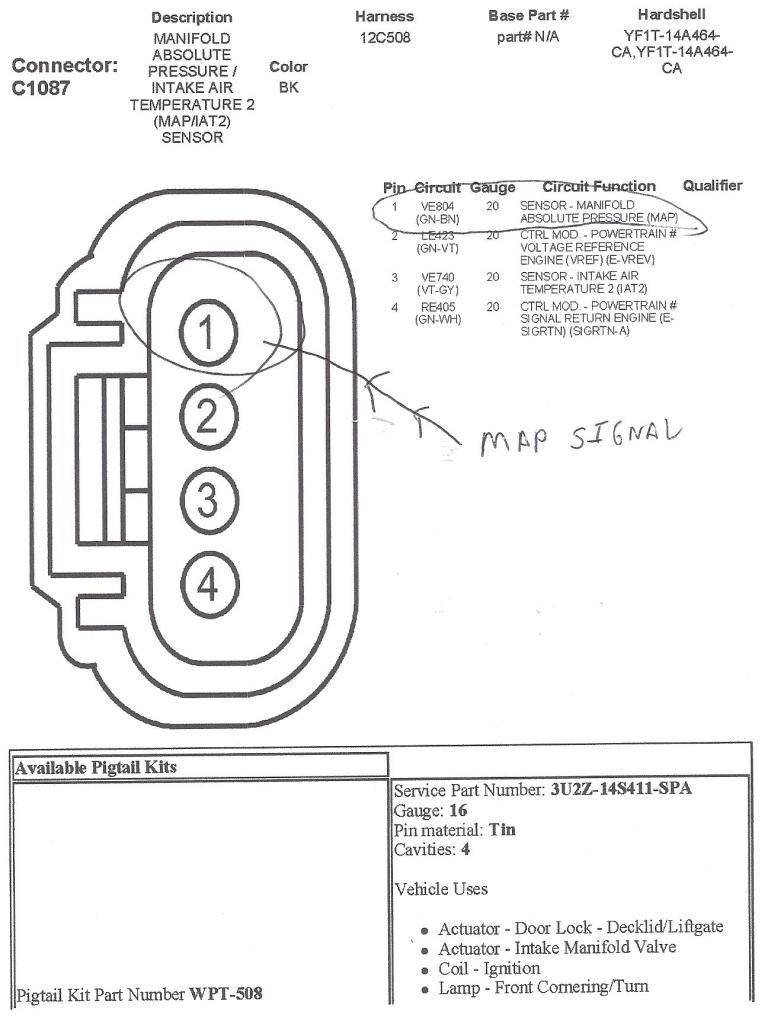

Back to the voltage question... Here is diagram graciously provided by BPD1151 in his original write up for installing the alky kits..

I used a razor, electrical tape, and a soldering iron to tap into that sensor... Since there is quite a bit of heat build up under the hood, it is required that you actually solder the additional signal wire to the original. If you rig with plastic a coupler you are asking for a failure...

The kit comes with an a appropriate gauge GREEN wire that you use to tap into your MAP sensor that then runs to the controller inside the car.. yes it has to go through the fire wall..

Final thoughts...

The materials in this kit are phenomenal... and its rated for any methanol mix you throw at it.. Snow is rated at 50/50 based on the fittings and hoses. This is what they told me when I called them... and I like not having to buy mixed or have to mix my fluids... I found that out while running E20 mixes.. I hated having to worry about the proper mix...

You CAN by Snow Boost Juice which is premixed 49 Meth / 51 Water but its $$$ compared to straight M1..

The controller on the Snow Stage 2 IS pretty cool and provides vastly more information than the Alky Kit.. and the Snow kit APPEARS to be much easier to install.. but I read several cases where the Snow controllers have failed. I have YET to find anyone claiming their Alky Controller has failed. So while it may not be as flashy... it appears to be very reliable which is more important to me when injecting meth..

That said, if you DO NOT have a way of monitoring your vehicles health with a a decent tool, then this kit is not for you OR go pay LMS to dyno tune it. Your MyCalibrator from LMS will NOT assist you in anyway what so ever in tuning for this kit. I use my SCTx4 to monitor and make adjustments, but if you are not comfortable reading datalogs, find a tuner who will help you AND understands how the Alky Kit works...

Brad has mentioned in a couple emails he really likes how the Alky Kit delivers the meth and controls the spray.. or it could just be that I know what I am doing on my end.. or I am just really lucky... lol

I did months of research of talking to people and companies before deciding on Alky... reputation is bar none...

I hope this helps!!!

Attached are pictures of what my tap looks like...

and just stops working.